You can repair the refrigerator yourself, but for this you need to have certain skills and knowledge. An important part of preparing for a repair is diagnostics, and for this you need to know how the refrigerator works. Let's try to figure out how the operation scheme of this common household device is organized.

The scheme of the refrigerator

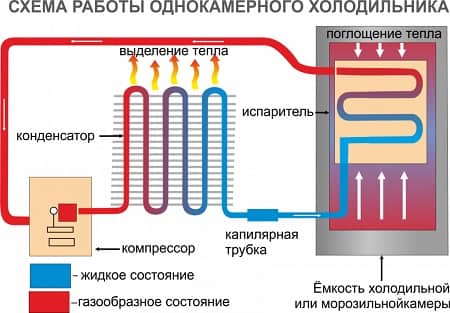

The refrigerator can be divided into three large parts. The failure of one unit makes the entire refrigerator inoperative, but does not affect the working state of other elements. The freezer consists of an evaporator, a condenser and a compressor. The compressor includes a relay and a motor.

The system of work is closed in nature. The refrigerant is pumped out of the evaporator by a compressor and then fed under high pressure to the condenser. In the condenser, it undergoes cooling, which contributes to the transition from the gaseous state to the liquid state, and then again moves to the evaporator, flowing naturally. So the work is repeated continuously.

Unlike other components, the compressor is not constantly on. It comes into operation by a signal from a temperature sensor when the temperature in the refrigerator exceeds the permissible norm. In this case, the relay drives the motor, as a result of which the compressor begins to perform its working function. When the temperature starts to be normal, the relay trips.

Compressor performance check

The first external sign of a malfunctioning compressor is an increase in temperature in the refrigerating chamber, up to its defrosting. Before starting to repair the compressor with your own hands, you need to figure out what exactly the malfunction of this device is. Getting to the compressor is not so easy - it is hermetically sealed with a casing where it is in oil.

Most compressors have a similar device. The main components are the motor and the starting relay. The relay closes when a signal from the sensor is received and starts the motor. If the motor does not start, the system will not function. In most cases, the problem when the compressor is not working is the motor. In such a situation, it is necessary to put a new motor, a little less often a complete replacement of the compressor of the refrigerator is needed. Let us examine the cases when it is easiest to repair and replace the refrigerator compressor.

Check current and resistance

The cause of a malfunction may be a cable; it is not so rare that a banal break becomes a source of serious problems.Replacing the cable is the simplest situation when repairs may come in handy. In any case, before starting any work on your own, you need to check the current and resistance, so as not to get injured.

To check the resistance, you need to find a place without paint or wipe it off a little with your own hands. Attach a multimeter to the contact and to the case, the device should not show any values, otherwise it is quite dangerous to continue repairing the refrigerator compressor with your own hands. For further work with the motor and start relay, safety precautions should be observed.

To check the current, a working relay is necessary, that is, before starting the test, you must be sure of its operability. It is most convenient to check the current with a multimeter, where the contact is made by ticks. With a motor power of 140 W, the current is 1.3 Amperes. The ratio remains the same for other engine power ratings.

![]() See also - Connecting the refrigerator compressor to a new device

See also - Connecting the refrigerator compressor to a new device

Causes of malfunctions

All malfunctions in the operation of the device can be conditionally divided into two types. In the first case, everything works well at first glance, that is, the motor is humming, the light is on. The cause may be a refrigerant leak, it is easy to check it yourself. It is enough to touch the capacitor, it must be very hot. If refrigerant leaks, the condenser will be at room temperature. The second common reason is a breakdown of the thermostat, that is, a signal about an increase in temperature is simply not received.

If the refrigerator does not turn on at all, then in 20% of cases the problem is reduced to a motor breakdown. If the motor is serviceable, but it is necessary to repair the compressor of the refrigerator with your own hands, you need to consistently check the main elements - the thermal sensor and relay. Each device must be replaced if it breaks down. If everything works well, you need to change the compressor itself, we will tell you how to do it yourself.

How to replace a compressor?

To repair a compressor yourself, you need to prepare the appropriate tools:

- storage for freon;

- lancing and sampling valves;

- burner.

It is recommended to use an oxygen-propane burner. Now you need to disconnect the device from the electrical network, free it from products and drawers with grills, and then proceed with the repair work.

The compressor must be pulled out and lifted slightly and the filling pipe must be broken. The device starts up for five minutes, during which the freon completely passes into the condenser. A piercing valve is connected to which a hose from the cylinder is connected. The valve is unscrewed for 30 seconds, this time is enough to collect all the gas.

Instead of a filling pipe, it is necessary to solder a copper one, it is for these purposes that a torch is used, but you can also use a conventional soldering iron. Then an incision is made on the capillary expander a few centimeters long, then the tube breaks, and the filter is sealed off from the condenser.

Now you need to completely disconnect the compressor from the pipes (most often there are two of them - to build up pressure and suck out excess gas), that is, the compressor must be unsoldered. To install a new compressor, you must repeat all steps in reverse order. After all work, make sure that the relay is working. If the launch was successful, then everything was done correctly.

See also:

terrible. thank.

In short, no master wants to delve into and announces such a price that it’s better to buy a new refrigerator