Today the food processor from Bosch and many other manufacturers has become almost indispensable devices in the kitchen. There are various modifications of these units that allow you to perform various tasks, and you will not make any special efforts. For some housewives, they have become very important, and any breakdown in the system becomes a serious problem. In this article we will tell you about the device design and how to repair food processors with your own hands.

Food processor device

The device consists of individual elements of the mechanism, the most basic elements are as follows:

- Electrical engine;

- processing product receiver;

- chamber for processing ingredients;

- sets of nozzles and knives;

- the main control panel of the combine;

- electrical wiring connecting the main elements.

The case material for combines is usually made of plastic. However, all other parts, such as attachments, knives and other elements are made of stainless steel, as it is durable, and it is on the inner parts of the device that the greatest load is placed.

![]() See also - 5 best food processor with grinder according to customer reviews

See also - 5 best food processor with grinder according to customer reviews

The main causes of malfunctions

Combines are divided into several types:

- mini;

- compact;

- multifunctional.

The last type of harvesters are those in which, for example, there is a combination of a meat grinder and a juicer. However, despite their different functional characteristics, they all have the same operating principle.

After loading the products into the working chamber of the combine, they are brought to the desired state according to the given program. Processes can be changed by replacing nozzles with them and giving the device the necessary commands. Nozzles come into motion thanks to the electric motor. It's easy enough to understand that your food processor needs urgent attention:

- new sound effects that the device has not previously emitted, for example - squeaks, knocks, rattles and others like them;

- you feel that an unpleasant smell of burning wiring comes from the car;

- cracks and chips have formed on the nozzles;

- the unit starts to work at an uneven pace, or it works in the wrong mode according to a given program;

- the device does not want to activate and start working.

As for the part for torque transmission, in some combines belt transmission is used to transmit torque to the main working bodies. When the device starts to perform poorly, it is possible that it is time to replace the worn out belt. There is also a keyed transmission of torque forces, in this case the key may wear out, which will also lead to the inoperability of the combine.

There are many options for harvester malfunctions, it is possible that some of its internal elements may fail, if one part fails, the whole mechanism may break. Also, not rivers are cases when problems arise in the wiring of the unit itself, when a short circuit occurs.

Harvester defective - what to do?

Any owners sooner or later will have to do it on their own repair your food processor. Before disassembling the food processor, make sure it is still under warranty after purchase. If there is one, then it is best to take the unit to a service center so that they provide the necessary service and return the combine to operability.

But as happens in most cases, breakdowns occur after the end of the warranty period, here it is already worth trying to disassemble and make food processor repair Bosch, before you go and take it in for repair, where you will be charged a lot of money for repairs.

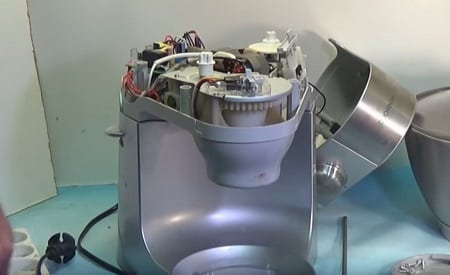

First of all, we disassemble the food processor, however, remember well what was removed and unscrewed from where, since you will have to assemble the unit back. All actions come down to the following:

- turn off the device from the mains and dismantle all removable parts;

- remove the combine and make sure the integrity of the belt and drive gears;

- remove the above items, and take out the engine. Inspect it for integrity and performance;

- Remove the protective cover from the gearbox and check the drive shaft for signs of defects.

If you have a different model, you can easily find videos and detailed instructions on the Internet.

When you are going to buy a replacement for some part, be sure to take the original ones, as third-party simply won’t be able to calmly stand in the groove. You can purchase such items in special service centers, or order them via the Internet.

Tips for extending the life of the combine

- It is best to process finely chopped products, and do not process frozen vegetables, meat and other things. It is also not recommended to crush solid ingredients;

- As soon as you feel an unpleasant smell coming from the combine, immediately turn it off in order to avoid a short circuit and prevent a breakdown;

- After you have finished the work, it is necessary to thoroughly rinse those elements of the combine that took part in the processing of products. Dry all parts thoroughly before reuse;

- Under no circumstances use attachments that have defects, this can harm the combine itself;

- After the warranty period has expired, it is best to regularly (at least once or twice a year) carry out preventive maintenance on the combine. Disassemble it and lubricate the necessary components of the mechanism, as well as replace worn-out parts of the device in advance, if they are found during disassembly, in order to avoid malfunctions in the future.

Conclusion

We have told you the main ways to make repair of food processors, and how best to avoid unpleasant situations with the breakdown of this device. In case of difficulties, it is recommended to contact the craftsmen who will find the malfunction and make high-quality and correct repairs.

Hello. The article is very helpful. What about the old combine harvesters? For example, how to disassemble and remove the casing from the Yugdon MK 112 combine. It has been working for 10 years and has never lubricated it. And then it got into it, but the case is not removed. Although all fastening screws have been unscrewed. Thank you in advance for your consultation.

There are no disassembly instructions for your model. Either you have very tight mounting slots, or somewhere hidden screws that you have not yet discovered.