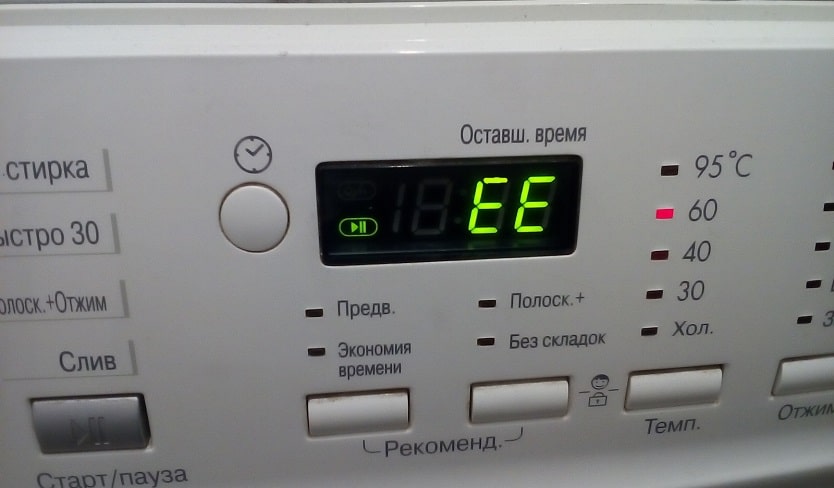

What should I do if the machine suddenly stops after starting the wash and the drain pump turns on? The same malfunction can occur immediately after pressing the start button. In a Samsung washing machine, errors are indicated by two numbers on the digital display or by flashing front panel lights. What does this mean?

Decoding the error

The E3, OE, OF, OC code on the display of the Samsung machine indicates the overflow of water. The pressure switch (water level sensor) signals that the washing machine is full of water, so it stops washing and starts draining the water. The different error indications depend on the model and year of manufacture of your washing machine.

Important:

Do not confuse error E3 with error 3E - these are completely different types of malfunction.

On Samsung machines without a display, all the LED indicators of the washing functions flash and two temperature indicators light up simultaneously - cold (Cold or 30 ° C) and 40 ° C.

In what cases can you eliminate yourself

- Lots of powder or handwash powder was added by mistake... This is the simplest reason for the error. Too much foam prevents the sensor from detecting the water level. Wait until it is completely empty, remove the laundry and start the rinse program. This will clear the powder and foam from the machine. Load the laundry again and start the wash.

- Water from the sewage system enters the machine (incorrect connection).The connection of the drain to the sewer must be carried out according to the instructions for the machine. It happens that the drain is connected to the siphon of the sink in the bathroom or in the kitchen, it gets clogged and the water rises in it, then it gets into the drain hose, and then into the tank of the washing machine. With this connection, it is necessary to constantly monitor the cleanliness of the siphons. Carefully inspect the drain connection and check it with the instructions.

- A failure has occurred in the control module... Turn off the machine, unplug it for a few minutes - this will reset all programs. Then plug in and start the wash.

![]() See also - Samsung washing machine gives error SUD (5UD) or SD (5D) - what does it mean?

See also - Samsung washing machine gives error SUD (5UD) or SD (5D) - what does it mean?

Faults requiring repair

When carrying out any work, you must first unplug the machine.

Blockage in the tube or air chamber of the pressure switch

The sensor needs to be cleaned. To do this, you need to remove the pressure switch from the machine, disconnect the air tube from the fitting and check both the sensor and the camera. The design of the pressure switch practically eliminates clogging, but the tube sometimes clogs. Rinse it with running water.

The reason for this clogging can be just dust.

Open in the water level sensor circuit

Check the connecting wires, external signs of this damage will be poor insulation and the actual wire break. If it is possible to connect, solder and isolate, if this is not possible, replace the entire loop.

The reason for this malfunction is the vibration of the machine. To avoid this and other damage related to vibration, it is necessary to set up the machine correctly, perhaps use silicone pads under the legs, observe the load norms of the machine and make sure that the laundry does not get tangled up.

Faulty pressure switch (water level sensor)

Before checking the sensor itself, pay attention to the attachment of the air tube to it. If the connection is loose and loose, there may be air leakage and the pressure generated is insufficient for normal operation of the instrument.

To check the pressure switch, attach a small tube of suitable diameter to its fitting and blow slightly. You should hear clicks. If not, the sensor is faulty.

The final stage of checking the device is a multimeter. When measuring the resistance at the relay contacts when it is triggered, the value should change.

Setting up and repair of pressure switch Is a job that requires qualifications and experience. Usually just buy a new one.

In order to buy a sensor, you need to know the make and model of the washing machine, since the pressure switches for all machines are completely different.

Electronic controller defective (control board)

In order to test the control board, it must be removed from the machine. Outward signs of a malfunction can be burnt board elements, soot, and the smell of burnt insulation. The cause of a breakdown is the failure of any element: resistors, transformer, relay and others. Repairing the control board is also quite complicated. Often it is simply changed to a new one.

The filler valve broke

To test the filler valve, it must be disconnected and removed from the machine. If it has cracks or deformation, it is needed valve replacement, it cannot be repaired. If the valve looks intact, then perhaps it just needs to be cleaned, and for this it is completely disassembled. The cause of the blockage may be scale. When disassembling, you also need to carefully inspect all parts for damage.

If you follow all the recommendations of the instructions for use, your washing machine will serve for more than one year without breakdowns. Modern washing machines are complex mechanisms, if you are not sure of your qualifications, then it is better to entrust the repair to professionals.

See also: