Pyrolytic cleaning is a fairly simple, but at the same time very effective and efficient way to clean the inner surfaces of the oven from accumulated deposits and grease. So what is it? How it works and what pluses and minuses it has.

What is pyrolytic cleaning

The meaning of the process of pyrolytic cleaning of the oven, what it is, becomes clear from the meaning of the word "pyrolysis" - "feast" - from the Greek "heat" and "lysus" - "disintegration, decay, decomposition." Purification is based on a chemical reaction that, when exposed to very high temperatures, causes complete decomposition of the starting material. Under the influence of temperature, the final rupture of intramolecular bonds occurs, as a result of which new compounds are formed. The whole process - pyrolysis - takes place without the participation of any chemical reagents, only under the influence of temperature, therefore it is also called "thermal" decomposition.

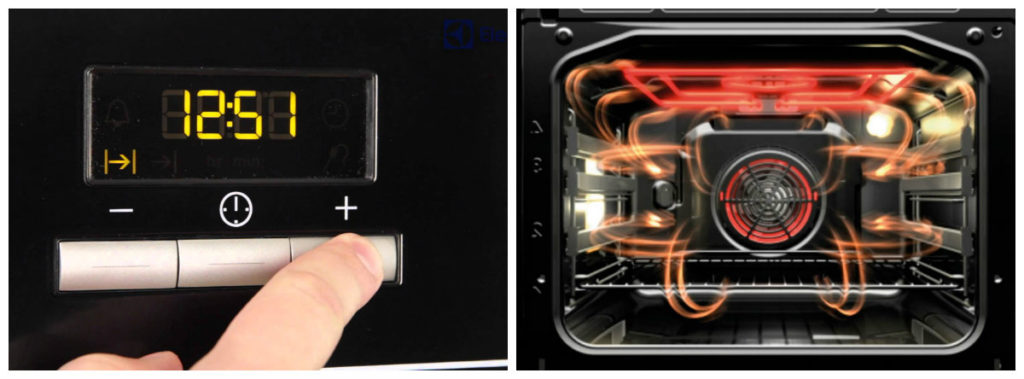

True, in order for the pyrolytic cleaning process (in fact, thermal decomposition) to begin, it is necessary to create a very high temperature inside the oven - about 450-500 ° C. With such a temperature effect, all organic compounds burn out and turn into ash. Which can be collected with a simple damp cloth after the oven has cooled down.

Important: Achieve a temperature of 500 ° C only in electric ovens. The maximum value in gas ovens is about 250 degrees. If the manufacturer indicates "pyrolytic cleaning" in the description of the gas oven, it means that he is simply trying to deceive the buyer.

In order for an electric oven to withstand such high temperatures, its interior must be made of very high quality heat-resistant steel. The oven door should also have a special multi-layer construction of tempered glass. All this, heat-resistant steel and a reinforced door - must provide a high level of thermal insulation so as not to damage the adjacent furniture or cause burns when accidentally touching the oven.

See also:

- 6 best ovens VEKO of the year

- 7 best Korting ovens according to customer reviews

- 8 best Hansa ovens of the year

- Hotpoint-Ariston's 8 best ovens

- The 8 best ovens in Gorenje

Preparation and cleaning

It is recommended to remove all racks and trays from the oven before cleaning. Most of them are not designed for such high temperatures, which can damage, for example, the non-stick coating. However, some models of electric ovens, especially premium ones, are equipped with baking sheets coated with heat-resistant enamel, so they can be left inside.

After this, the pyrolytic purification process can be started directly. When the function is started, the oven door should automatically lock. It can only be opened after the inside temperature drops below 200 ° C. But, even though the door is locked, glass, especially for low-cost models, can heat up to 90 degrees, so at this time it is better not to let children into the kitchen.

The frequency of cleaning directly depends on how often you use the oven and what dishes you prefer to cook in it. Manufacturers recommend cleaning at least 1 time per month. Modern models of electrical cabinets are equipped with a special catalyst. It determines how dirty the internal surface of the oven is, gives a signal about the need for cleaning, and determines the time required for the complete cleaning operation.

Important: Do not clean the oven too rarely. Dirt that accumulates on the walls for a long time is very difficult to decompose thermally. This leads to an increase in cleaning time, as a result - a large consumption of electricity, as well as the appearance of a strong smell of burning.

Some models of electric ovens have several degrees of pyrolytic cleaning, which differ in temperature. This makes it possible to choose the cleaning option in the "gentle" mode, at lower temperatures, saving electricity.

![]() See also - Hydrolysis cleaning of the oven - what is it?

See also - Hydrolysis cleaning of the oven - what is it?

Advantages and disadvantages

Let's evaluate the pros and cons of pyrolytic cleaning of the oven. First of all, the main advantage of this method is that self-cleaning of the electric oven occurs almost without human intervention. Other benefits worth noting:

- high efficiency - the pyrolytic process allows you to get rid of even old spots of fat, you would have to make significant efforts manually to achieve this effect;

- suitable for all types of pollution - dairy, fatty, sugar, dough, etc., equally well destroys any type of pollution;

- cleaning the entire surface - there are enough hard-to-reach places in the oven to wash them by hand;

- lack of chemicals, after which a characteristic smell may remain for a long time, which negatively affects the taste of the cooked food.

Minuses:

- high cost - the need to use high-strength heat-resistant steel and tempered glass to provide thermal insulation significantly increases the cost of electric ovens;

- process duration - in order to clean surfaces well, it is necessary to maintain a high temperature in the oven for up to 2 hours. The longer the periods between cleaning, the longer it may take for the accumulated dirt to decay;

- high energy consumption - on average, one cleaning procedure will require 4 to 7 kilowatt-hours of electricity. The greater the pollution, the greater the energy consumption;

- special requirements for furniture - despite the thermal insulation, the oven (especially the cheap models of “gray” manufacturers) can be significantly heated. Therefore, the furniture where the oven will be built in must withstand a significant temperature load, which can exceed 70 ° C. In models of leading manufacturers, this drawback is practically not manifested, but additional thermal insulation affects the cost;

- unpleasant odor - special filters are built into the oven that must suppress the smell of burning fat. But if there is a lot of grease and dirt accumulated, then they will not be able to effectively cope with the intense odor, so it is better to use an exhaust hood in addition.

See also: