It is quite common, the washing machine seems to turn on and hums, but water does not enter the drum. An equally common problem is that water still enters the washing machine, but very badly, and the wash takes many hours.

If this happens, you do not need to immediately start to panic and look for the phone number of the nearest service center. It is possible that you will be able to cope with this breakdown on your own. We suggest that you familiarize yourself with the basic recommendations of the masters on how to cope on your own if the washing machine hums, but water does not enter the drum.

In fact, the reasons that cause such problems can be different. This can be mechanical damage, various blockages or a failure in electronic control. To do washing machine repair and return the equipment to normal operation, you need to accurately determine the cause of the problem. Only then will it be clear what to do. So what are the main reasons that the washing machine does not draw water?

Problem in the plumbing: remedies

If water does not flow into the machine at all or is poured too poorly, immediately check the water pressure in the water supply system. It is possible that at this time the water supply system is being repaired by utilities, and an accident on the pipeline is also possible. While you rush about, not knowing what to do, and curse your hapless washing machine, utilities may take their time to make some kind of planned repairs. Or the water was cut off due to an emergency.

If the water supply is in order and your plumbing is not satisfactory, you need to examine the water supply hose and the tap itself. It is not uncommon that the water supply tap turns out to be closed and the machine does not receive water into the drum of the washing machine, and the reasons lie most often in the forgetfulness of the owner or the pranks of children. It also happens that the elastic water supply hose simply twists, breaks or gets pinched.

If everything is normal here, it's time to examine the inlet hose filter, which protects the washing machine from debris from the water supply. To inspect the filter, you just need to remove the hose from the tank, and at the same time clean it from plaque. You just need to hold it for some time under a good pressure of water, although it does not hurt to walk on it a couple of times with a brush. At the same time, the water supply hose itself should be rinsed in the same way. In order not to prevent such a situation in the future, it is necessary to clean the filter and the water supply hose every six months.

![]() See also - Why did the washing machine stop spinning the laundry?

See also - Why did the washing machine stop spinning the laundry?

Washing machine inlet valve problem

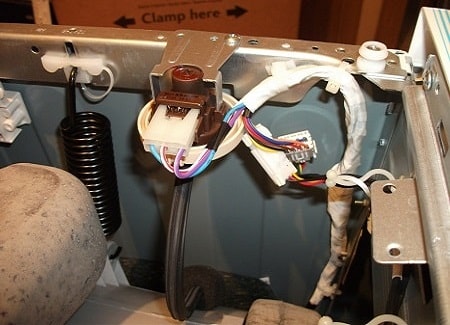

Washing machine valves are single, double or triple. That is why some washing modes can work properly, while others do not get water well into the washing machine drum. To check each valve, the washing machine will need to be disassembled. You will have to remove the top cover, right under it you will immediately find the outlet valve, which is located at the top of the back wall. By the number of channels, you will see the coils, which, with their cores, block and open the passage of water. You will also see a reducer that reduces the water pressure at the common inlet. It is a rubber washer that must also be removed and rinsed with water. This must be done very carefully, because if dirt gets into some kind of inner membrane, the valve will constantly let water through and it will be almost impossible to repair it.

How are coils arranged? Each of them has a core that rests on a diaphragm with a hole made in the center. If everything is in order, this system is always closed by the pressure return spring. In the case of power supply to the coil, the stem moves away. That is why water flows freely in each wash cycle. Thus, by applying an electric current to each of the coils and disconnecting the terminals, it is possible to check the flow of water through each channel.

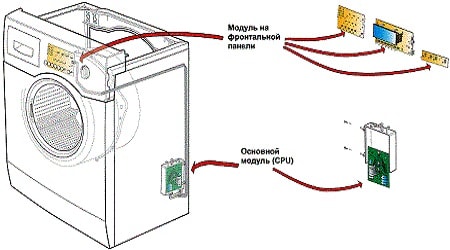

Defective programmer or control module

The reason for the poor flow of water into the machine may be hidden directly in the programmer. You need to understand that the more electronics in your machine, the more likely a breakdown of this kind is. Most often, such problems begin after three to four years of operation, especially in conditions of constant violation of operating rules. If the reason is in the programmer, then the outlet valve is working properly, and the command to start the water simply does not come. Therefore, the cause of the breakdown should be looked for in the electronic filling. Immediately you need to tune in to what to fix yourself control module it will be very difficult. The electronic controls are subject only to specialists. An attempt to repair yourself only threatens to worsen the situation and increase costs.

Defective pressure sensor

A breakdown of the pressure sensor, it is also a pressure switch, also leads to a weak flow of water into the machine. This sensor is designed to control the amount of water entering the machine. When there is not enough water, the sensor simply does not allow washing. If the sensor is broken and unable to estimate the volume of incoming water, it simply stops flowing. This reason requires replacement of pressure switch, which you can do yourself or contact a specialist.

Broken hatch lock

This is a relatively common cause of washing machine breakdowns. The door does not open or does not close tightly, this may be the reason why the washing machine does not collect water. Then you just need replace the sunroof locking device... There are other reasons for the failure of the door locking device. For example, it can be loose hinges or a damaged door tongue. Repair consists most often in replacing the hatch, although experienced craftsmen can also replace individual parts of the locking devices, but all the same, repairs require a complete dismantling of the door. And saving on details can turn into unnecessary costs for paying for the work of the master.

See also: