In order to avoid risks in the operation of the washing machine, all details must be taken into account when installing it. As a protection against the effect of drawing water back into the tank, which often happens, a check valve is installed for the washing machine. In this article we will talk in detail about the types of check valve (anti-siphon), the function and how to install it.

Varieties and functions of the check valve

Dirty water can enter the tank if the washing machine is not properly connected to the sewer. This entails negative consequences: linen deteriorates, a large amount of electricity is consumed. An anti-siphon prevents wastewater from entering the washing machine tank and thus protects the drainage system from contamination.

The device provides unimpeded drainage of water from the washing machine. Thanks to a special shutter, water from the sewer system does not leak back into the tank. Having an idea of the types of valves and their manufacturers, you can choose a really high-quality drain with antisiphon. Today in the markets you can find the following types of check valves:

- mortise;

- washing;

- wall;

- non-separable;

- segmented

All of them perform the function of ensuring the correct discharge of water and practically do not differ. However, when installing a washing machine of a certain brand (for example, LG), a segment valve may be required, which can be easily disassembled and cleaned of various debris. A non-separable type device is suitable if there is not hard water in the water supply. But even in this case, within 2-3 years, its replacement will be required.

A wall valve is expensive. This option is used to install drain communications in a narrow gap between the back of the washing machine and the wall. This compact anti-siphon has an aesthetic appearance.

When connecting a direct drain to the sewer pipe, the best option is to install a mortise device. The non-return valve is inserted into a specially prepared insert. The washing antisiphon is designed for installation in sink siphons of any kind.

![]() See also - How to independently change the bearing in the washing machine

See also - How to independently change the bearing in the washing machine

What check valves do experts recommend?

- The valve is made of polypropylene wall type, production - Czech Republic, the company "Alcaplast". High-quality device, affordable, suitable for any drain hose. Used as an end fitting with a sewer pipe, it provides reliable discharge of waste water from the washing machine.Chrome antisiphon with a spring mechanism and a reflector decorating the mounting location. The approximate cost is $ 8.

- Check valve made of mortise-type polypropylene, manufactured by Italy, Siroflex. The mechanism is installed in the hole in the sewer pipe or serves as a fixture for the drain hose. The device is represented by a stainless steel spring and a rubber membrane. Provides effective drainage protection. The approximate cost is $ 7.

- Segment polypropylene antisiphon, production - Italy, firm "Merloni". This backpressure valve is mounted under a sink. It is easily disassembled and cleaned in case of contamination. The mechanism is a spring with a rubber membrane. Provides a normal drain of a water stream from a tank. The approximate cost is 8.5 dollars.

The principle of operation of the anti-siphon valve

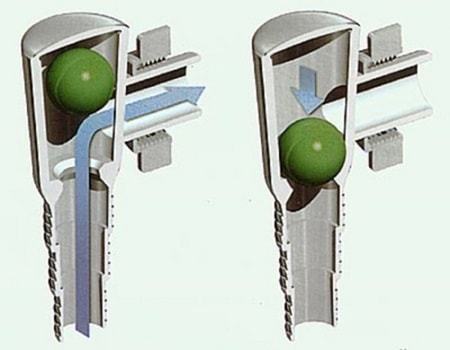

The non-return valve is a common mechanism and works according to a simple scheme. A tube of a certain shape, with a spring or ball type valve, is installed on the sewer pipe, siphon or drain hose. During discharge, water under pressure enters the antisiphon and flows through it into the sewer. In the event of a back pressure, water will not leak out, since the mechanism does not open inside.

When using a spring valve, the drainage system is protected against leakage of dirty water by a spring and a rubber membrane that creates a damper. In a ball check valve, a rubber ball serves as a shutter. It is pressed against the membrane under the influence of pressure. The built-in ribs clean the ball.

Antisiphon Installation

You can install the check valve yourself. But it is necessary to take into account all its design features. Despite the distinctive details, in any case, the work is done on the same principle.

The antisiphon consists of a tube with two exits (from opposite ends) of various diameters. On the one hand, the valve tube must be connected to a siphon or mounted in a cut-out in a sewer pipe, and on the other hand, it must be connected to the drain hose of the washing machine. Then you need to do it yourself with high-quality sealants with the help of sealant all the joints, after which the work can be considered finished.

For normal operation of the washing machine, an anti-siphon is not always required. Experts say that the installation of this mechanism is relevant in the case of:

- direct connection of the washing machine to the drain pipe, which is cut very low and there is no way to raise it;

- connecting the drain hose to the siphon located under the sink.

An anti-siphon device is not necessary if the washing machine is connected in accordance with all the rules and the drain pipe is raised to the required height.

However, the washing machine smells of an unpleasant odor, and at the same time the washed items remain dirty after washing, it is necessary to purchase an anti-siphon, the installation of which can be done by yourself. In such a situation, there is no alternative solution to the problem!

Summing up, it should be noted that the organization of the discharge of waste water from the tank of the washing machine should be carried out in accordance with all the rules. If a “siphon effect” occurs, an anti-siphon mechanism is required. Despite the simplest design, the device is indispensable for leaking dirty water back into the apparatus. Some washing machines are sold with check valves. But also the device can be bought separately.

It is very important to choose the type of antisiphon that will correspond to the drainage device. In addition, you should seriously approach installation work - you must reliably seal all parts so that there are no leaks.

See also: