You do not know what happened to your washing machine, because of which it began to jump, vibrate violently and make uncharacteristic sounds? Perhaps she moved off her legs or became wrong. But also strong vibration can indicate a more serious problem that needs to be addressed immediately. So it can cause noise. We’ll try to figure it out before this problem gets worse.

Why does the washing machine start jumping during spin cycle

There are a lot of reasons why the washing machine jumps and makes stronger noises. Let's look at what kind of malfunctions can cause strong vibration of the washing machine:

- When washing small objects can get between the drum and the tank, for example, sometimes we can wash things with coins, paper clips, bedding with pins or small buttons and fasteners get caught.

- If the transport bolts were not unscrewed during installation.

- Incorrectly distributed linen in the drum of the machine (found in older models of washing machines).

- If your motor is broken.

- The washing machine is not correctly installed on the supports.

- Check if bearings are out of order.

- Faulty or heavily worn springs and shock absorbers.

- Another reason may be a weakening of the mount or deformation of the counterweight.

![]() See also - The washing machine constantly draws water and immediately drains - what to do?

See also - The washing machine constantly draws water and immediately drains - what to do?

Troubleshooting

The problems are manifold, and it’s very difficult to immediately find out what could cause strong vibrations. Therefore, it will be more rational to exclude, at first the simplest options, the washing machine rumbles and shakes. What to do to find out the simple reasons why the washing machine jumps during the spin cycle:

- Take a close look to see if the laundry is wrapped in a knot, it often happens that small items of clothing are clogged in a duvet cover or sweaters.

- You should check whether the volume of laundry in the machine exceeds the maximum permissible. For each washing mode and machine models, different allowable indicators are possible.

- Noise can occur when things occupy more than 2/3 of the volume of the drum.

In such cases, some washing machines are equipped with a special sensor that displays errors of the type: UE or UB on the display.

How to install a washing machine so that it does not jump?

Strong vibrations can often be caused by incorrect installation or typical errors, especially when the equipment is not installed by professionals or installation is done independently. The most common mistakes are shipping boltswho simply forget to remove or install the device unevenly or put on a slippery surface (tile), which causes staggering and, as a result, a loud noise.

Why the washing machine jumps when installed incorrectly and what to do:

- The first thing you need to remove the transportation fasteners. They are installed to fix the drum so that it is not damaged during transportation. If they are not removed, the drum will spin, but its wear will be greatly increased, and the operation of the device will be accompanied by strong vibration and bouncing.

- Carefully watch that the equipment is installed strictly according to the level. To do this, you can twist the legs and adjust their height. During the spin, the machine enters into resonance and can even move around the room, therefore it is not recommended to leave the faulty equipment in working condition unattended.

- After the installation is completed, check if the device is staggering. Any, even the slightest stagger can lead to bouncing. If the washing machine is staggering, then it will have to be aligned.

Even if the equipment will be installed by professionals, it is better to independently check these nuances to make sure that everything is in order. Be sure to test the work after installation. Such actions will help you save time on the subsequent recall of the installers, so that they fix the problem and not wonder what to do so that the machine does not make frightening sounds.

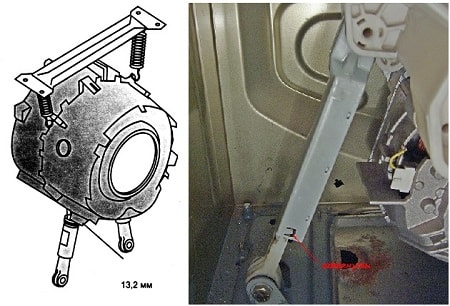

Defective shock absorbers

It is necessary to inspect the shock absorbers, which serve to mitigate the blows during the movement of the drum, reduce loads and dampen vibrations. If the device vibrates violently or jumps, then perhaps the shock absorbers will have to be replaced. Shock absorbers are mounted together with spring mechanisms, but if only shock absorbers are worn out - they can be replaced separately, if the springs are out of order, then you will have to change everything all at once. Over time, the shock absorbers wear out and cannot be repaired - immediately change. Depreciation may be uneven, but if only one is faulty, both shock absorbers must be replaced so that there is a balanced load distribution.

Look, maybe small things are stuck under the drum. If they are, then you have to get them. For example, a bone from a bra or a clip can be easily taken out, if you pick it up with something, you can do something like a hook, which will be convenient to pull out small parts. If you get stuck in smaller parts that you can’t get out, you will have to disassemble the washing machine. To do this, remove the heating element, drum and some other parts. If you have never disassembled washing machines, then it is better to call a wizard who will do this as quickly as possible, which will save you a decent time, but most importantly, it is safe for technology.

![]() See also - The bone from the bra got into the washing machine

See also - The bone from the bra got into the washing machine

Problems with securing counterweights

If the washing machine began to vibrate violently and jump, you need to check the operation of the counterweight. We open the lid in the upper part of the device, for this you may need tools, it will be enough to use keys, a screwdriver and pliers. We look at the state of the counterweight, it is a weighting agent, which is made of different materials. Such parts are installed at the top and bottom of the washing machine. They can be made of concrete, cast iron, or other heavy material.

What to do next:

- We look at the mounts, if they loose, then they will need to be tightened.

- If you can’t tighten the fasteners, you will have to purchase and install new ones.

- If the weighting agent itself is deformed, one cannot do without replacing it with the same one.

One of the reasons a machine can jump is a bearing breakdown. The replacement process is technically complex, so it is better to call a master who can do this job in a high-quality manner.If you still want to do this yourself, you will need more information about this process, so you can read the corresponding article about it.

Bearing problem

Faults associated with bearing failure are far from a rare occurrence. The main reasons for the breakdown of this part are due to the fact that the metal from which the elements are made collapses over time due to exposure to water. When the bearings begin to collapse, the operation of the apparatus will first be accompanied by increased vibration and noise, and then the drum may jam completely.

When the bearing is just starting to break, identifying problems is difficult. Usually, professionals can tell about the wear of a part by sound, but for this you need to have experience and knowledge. But when the bearing is already badly damaged, you can move the drum. When he moves in different directions, it says that it’s time to call the master to replace a worn bearing.

What can we talk about in the end? It turns out that the washing machine is a complex system that needs professional help to fix technical problems and it is worth contacting qualified specialists with experience and knowledge to quickly and effectively fix the problem.

See also: